Ice Plant / Concrete Cooling

Adding ice to the concrete mix is also an effective solution to cooling the concrete. The produced ice is cooled in concrete production by adding concrete mixture with different options. In addition, concrete can be cooled by adding ice to the water tank.

Ice machines in different options may be preferred.

Block Ice production and Flake Ice production systems;

The Block ice production systems; It is a system that enables ice to be added to the water tanks in the concrete batching plant at the mold at -12 ° C in the ice system, thus cooling the water used in the concrete.

We usually recomended Containerized type 5 Ton/day capacity block ice plant or Containerized type 10 Ton/day capacity ice block ice plant.

The Flake Ice production systems; It is a system that produce full automatic flake ice and store the ice in Ice Storage systems. The ice an be transferred to the water tank in the concrete plant to cool the water and it can be added to the concrete mixture fully automatically by attaching to the aggregate band.

To add ice to concrete mix, we integrate the control of ice plant to automation system of batching plant. The sytem works automaticly controled by batching plant. In this case the user can arrange the amount of ice for per meter cube of concrete.

For chose the right ice machines for the concrete production, we help to our customer and consulate also. We study on the concrete plant and find the actualy temperature of concrete. Than we can recommend the best option for our customers.

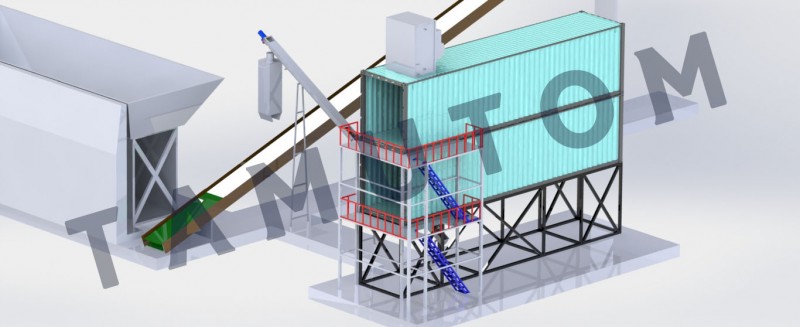

We manufacture our facilities in mobile form with 20 "or 40" containers with all equipments (electrical, water, lighting, cooling group). Shan container ice facilities can also be used as mobile facilities in construction sites around the world.

In addition, our machines, which we also make as Modular Type, can be used in concrete plants.

Today, the Construction Leader's of the World has been choose the ROSEN for cooling technogies,

- ISO 9001 Quality Management Certificate

- CE Certificate